/home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/861/header-lBanner.php on line 27

https://www.wahmg.com/)">

https://www.wahmg.com/)">

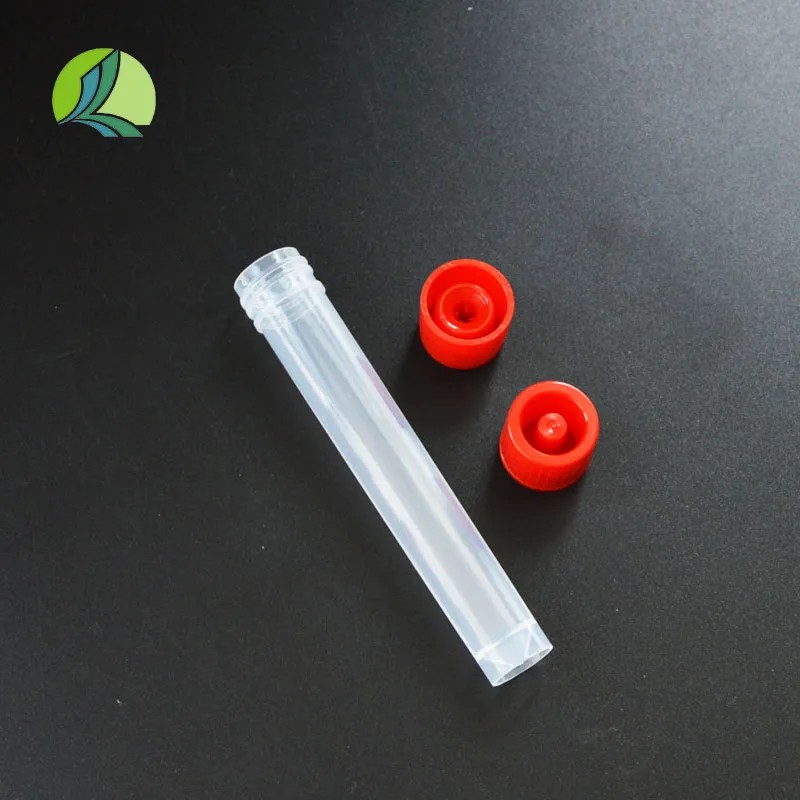

Virus Sample Tube

1 月 . 15, 2025 09:15

Back to list

Virus Sample Tube

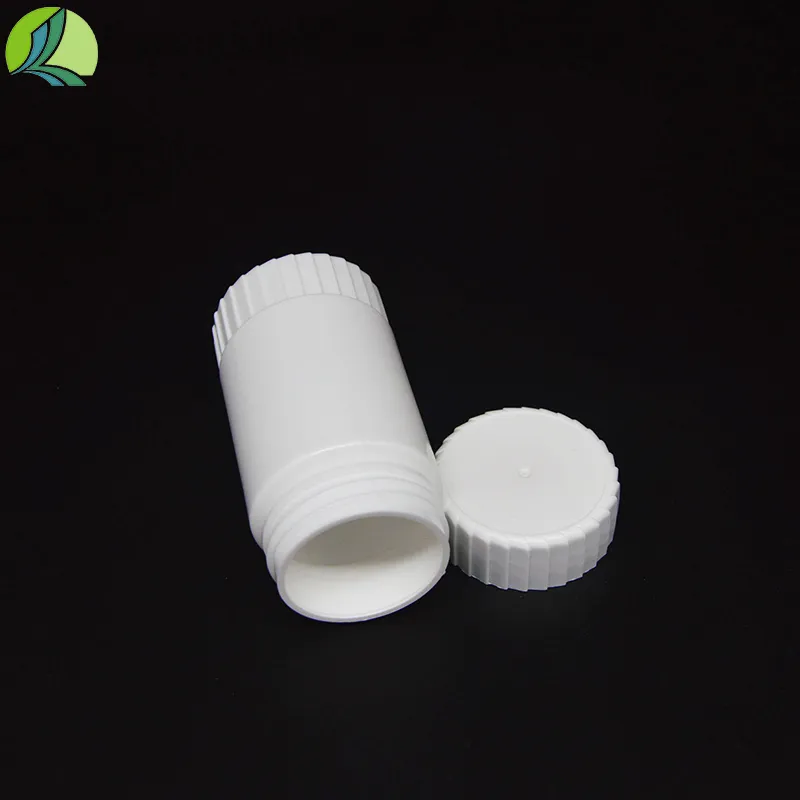

The 10 ml injection vial has become an essential component in the healthcare and pharmaceutical industries, serving as a crucial vessel for storing and administering medications. These vials provide functionality with precision, and it's vital to understand the extensive expertise involved in their design and application to appreciate their significance.

In the context of patient experience, the use of 10 ml injection vials is equally paramount. Healthcare providers appreciate their straightforward design, which simplifies the process of drawing and administering medication safely. The transparency of the materials allows for easy inspection of the vial's contents, ensuring that healthcare professionals can visually confirm the medication's quality before use. This feature contributes significantly to patient safety, which is at the heart of every medical endeavor. For patients, the design considerations of these vials translate into a seamless treatment experience. Accurate dosages mean effective treatments, reducing the risk of side effects and enhancing recovery. This attention to detail, overseen by industry experts, builds confidence and trust in the care being received. The authority of 10 ml injection vials extends beyond practical usage; they embody the trust between pharmaceutical companies, healthcare providers, and patients. This trust is cultivated through an unwavering commitment to quality and safety, driving continuous innovation in their design and application. At the intersection of cutting-edge science and compassionate care, these vials represent the integrity of the medical field. In conclusion, 10 ml injection vials play an indispensable role in the healthcare continuum. They stand as a testament to the meticulous planning and comprehensive expertise that governs their creation and utilization. With safety and functionality at their core, these vials exemplify an industry-wide commitment to excellence, ensuring that they remain a trusted choice in medical environments worldwide.

In the context of patient experience, the use of 10 ml injection vials is equally paramount. Healthcare providers appreciate their straightforward design, which simplifies the process of drawing and administering medication safely. The transparency of the materials allows for easy inspection of the vial's contents, ensuring that healthcare professionals can visually confirm the medication's quality before use. This feature contributes significantly to patient safety, which is at the heart of every medical endeavor. For patients, the design considerations of these vials translate into a seamless treatment experience. Accurate dosages mean effective treatments, reducing the risk of side effects and enhancing recovery. This attention to detail, overseen by industry experts, builds confidence and trust in the care being received. The authority of 10 ml injection vials extends beyond practical usage; they embody the trust between pharmaceutical companies, healthcare providers, and patients. This trust is cultivated through an unwavering commitment to quality and safety, driving continuous innovation in their design and application. At the intersection of cutting-edge science and compassionate care, these vials represent the integrity of the medical field. In conclusion, 10 ml injection vials play an indispensable role in the healthcare continuum. They stand as a testament to the meticulous planning and comprehensive expertise that governs their creation and utilization. With safety and functionality at their core, these vials exemplify an industry-wide commitment to excellence, ensuring that they remain a trusted choice in medical environments worldwide.

Share

Prev:

Latest news

-

Wholesale Plastic Juice Bottles with Caps 16 oz Options Available Bulk Packaging SolutionsNewsJun.10,2025

-

Laboratory Apparatus Reagent Bottle – Durable & Chemical Resistant Bottles for Safe StorageNewsJun.10,2025

-

Squeezable Dropper Bottles Durable, Leak-Proof & CustomizableNewsMay.30,2025

-

Affordable Plastic Petri Plates Sterile & Disposable Lab-GradeNewsMay.30,2025

-

Eye Dropper Caps Precision 24/410 & Plastic Bottle-Compatible TipsNewsMay.30,2025

-

Affordable Mini Spray Bottle Price & Wholesale Deals Shop NowNewsMay.29,2025

RECOMMEND PRODUCTS