/home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/861/header-lBanner.php on line 27

https://www.wahmg.com/)">

https://www.wahmg.com/)">

Drop Bottle Plastic Drop Bottle Eye Medicine Bottle

2 月 . 13, 2025 19:16

Back to list

Drop Bottle Plastic Drop Bottle Eye Medicine Bottle

Exploring the Evolution and Versatility of 2 ml Plastic Dropper Bottles

Environmentally conscious consumers will find reassurance in the ongoing innovations aimed at transforming these plastic bottles into more eco-friendly versions. With increasing concerns over plastic waste, manufacturers have begun adopting recycled materials and biodegradable plastics, evolving their designs to minimize environmental impact without compromising on quality. While traditionally made dropper bottles continue to hold their ground due to their recyclability and robustness, the emergence of sustainable options signals a shift towards a more environmentally responsible packaging industry. For retail and commercial settings, the authority of 2 ml plastic dropper bottles extends beyond mere packaging; they influence purchasing decisions. Professional packaging consultants agree that the right packaging can enhance perceived product value, making these bottles a sound choice for small-scale, high-value products. They offer an excellent balance of aesthetics and practicality, often playing a crucial role in brand differentiation and customer satisfaction. The trustworthiness of these containers has been continually validated by industry standards and certifications. From being BPA-free to ensuring no chemical interference with the contents, every aspect of these bottles is focused on maintaining the consumer's trust. The assurance of a non-reactive and safe container plays an instrumental role in quality assurance for any brand aiming to retain their customer's loyalty and confidence. In conclusion, the 2 ml plastic dropper bottle exemplifies a fusion of science, practicality, and innovation. Its multifaceted benefits make it an essential component across a diverse range of sectors. With ongoing advancements in materials and production techniques, the future of these ubiquitous bottles looks promising, with continued efforts to enhance their functionality, sustainability, and effectiveness. As industries evolve, these little dropper bottles will undoubtedly continue to serve as a prime example of how precise, effective engineering meets practical, everyday needs.

Environmentally conscious consumers will find reassurance in the ongoing innovations aimed at transforming these plastic bottles into more eco-friendly versions. With increasing concerns over plastic waste, manufacturers have begun adopting recycled materials and biodegradable plastics, evolving their designs to minimize environmental impact without compromising on quality. While traditionally made dropper bottles continue to hold their ground due to their recyclability and robustness, the emergence of sustainable options signals a shift towards a more environmentally responsible packaging industry. For retail and commercial settings, the authority of 2 ml plastic dropper bottles extends beyond mere packaging; they influence purchasing decisions. Professional packaging consultants agree that the right packaging can enhance perceived product value, making these bottles a sound choice for small-scale, high-value products. They offer an excellent balance of aesthetics and practicality, often playing a crucial role in brand differentiation and customer satisfaction. The trustworthiness of these containers has been continually validated by industry standards and certifications. From being BPA-free to ensuring no chemical interference with the contents, every aspect of these bottles is focused on maintaining the consumer's trust. The assurance of a non-reactive and safe container plays an instrumental role in quality assurance for any brand aiming to retain their customer's loyalty and confidence. In conclusion, the 2 ml plastic dropper bottle exemplifies a fusion of science, practicality, and innovation. Its multifaceted benefits make it an essential component across a diverse range of sectors. With ongoing advancements in materials and production techniques, the future of these ubiquitous bottles looks promising, with continued efforts to enhance their functionality, sustainability, and effectiveness. As industries evolve, these little dropper bottles will undoubtedly continue to serve as a prime example of how precise, effective engineering meets practical, everyday needs.

Share

Latest news

-

Wholesale Plastic Juice Bottles with Caps 16 oz Options Available Bulk Packaging SolutionsNewsJun.10,2025

-

Laboratory Apparatus Reagent Bottle – Durable & Chemical Resistant Bottles for Safe StorageNewsJun.10,2025

-

Squeezable Dropper Bottles Durable, Leak-Proof & CustomizableNewsMay.30,2025

-

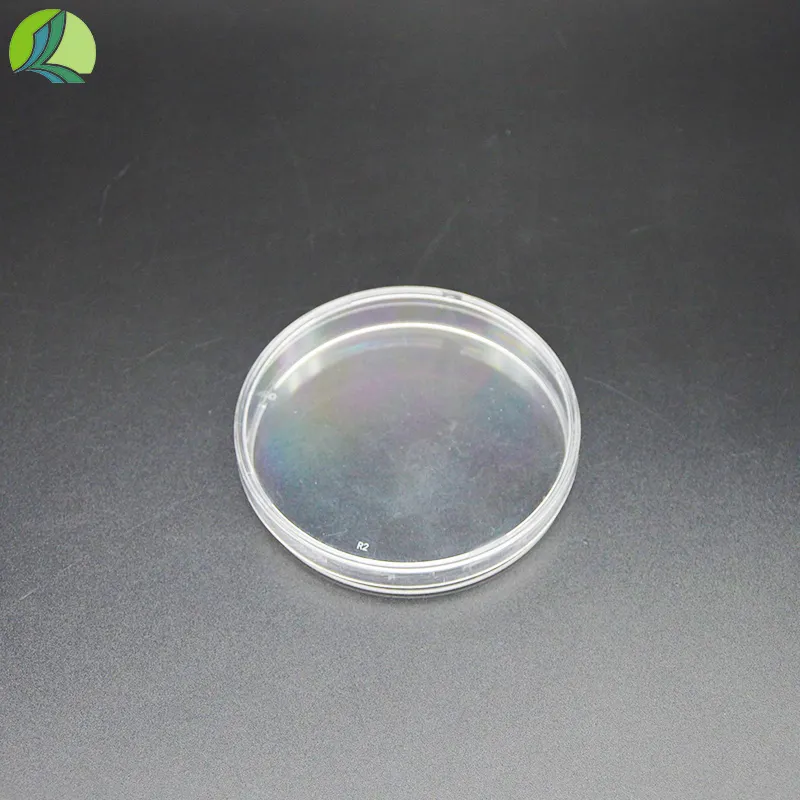

Affordable Plastic Petri Plates Sterile & Disposable Lab-GradeNewsMay.30,2025

-

Eye Dropper Caps Precision 24/410 & Plastic Bottle-Compatible TipsNewsMay.30,2025

-

Affordable Mini Spray Bottle Price & Wholesale Deals Shop NowNewsMay.29,2025

RECOMMEND PRODUCTS