/home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/861/header-lBanner.php on line 27

https://www.wahmg.com/)">

https://www.wahmg.com/)">

plastic reagent bottle factory

2 月 . 03, 2025 03:47

Back to list

plastic reagent bottle factory

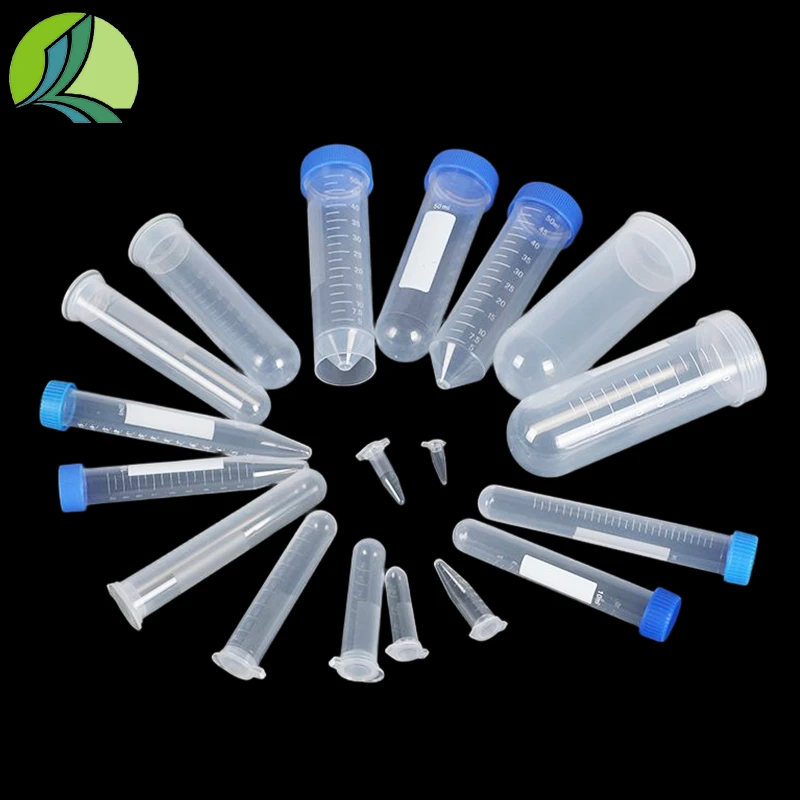

The extraction reagent bottle, an unsung hero within laboratories and industrial settings, plays a pivotal role in ensuring efficiency and precision within extraction processes. This seemingly simple container, engineered with care, is designed to store, dispense, and preserve various chemicals essential for successful extractions.

From an expert perspective, understanding the nuances of how an extraction reagent bottle influences the chemical interactions and stability of reagents is crucial. These bottles are designed to maintain an inert environment, thereby extending the shelf life of sensitive reagents. The engineering behind these bottles often includes UV-resistant materials to shield light-sensitive reagents, ensuring they remain potent until they are required for use. Authoritative insights into the performance of extraction reagent bottles reveal their critical role in compliance with industry standards. Regulatory bodies often scrutinize the storage conditions of chemical reagents, and using certified bottles that adhere to standards such as ISO and ASTM can vastly affect the approval process of laboratory procedures and outcomes. Such compliance not only highlights the authoritative significance of using the right bottle but also builds trust with clients and stakeholders who rely on accurate and reproducible results. Trustworthiness in the context of extraction reagent bottles stems from their role in guaranteeing the purity and performance of the stored reagents. Laboratories are environments where precision is non-negotiable, and the trust placed in these bottles is immense. An anecdote often shared among seasoned lab professionals is that of the occasional venture when substituting reagent bottles resulted in altered extraction efficiencies. This narrative underscores the critical contribution of a reliable extraction reagent bottle in preserving the integrity of reagents, thereby ensuring consistent and trustworthy outputs. In conclusion, the extraction reagent bottle is an indispensable asset for any laboratory or industrial operation involved with chemical extractions. By selecting the right bottle, professionals can enhance their operational efficiency, uphold high standards of safety and compliance, and foster an environment of trustworthiness. As technology advances, the development of even more sophisticated reagent bottles will undoubtedly continue to support the ever-growing demands for precision and safety in chemical processes, cementing their role as vital components in the scientific community.

From an expert perspective, understanding the nuances of how an extraction reagent bottle influences the chemical interactions and stability of reagents is crucial. These bottles are designed to maintain an inert environment, thereby extending the shelf life of sensitive reagents. The engineering behind these bottles often includes UV-resistant materials to shield light-sensitive reagents, ensuring they remain potent until they are required for use. Authoritative insights into the performance of extraction reagent bottles reveal their critical role in compliance with industry standards. Regulatory bodies often scrutinize the storage conditions of chemical reagents, and using certified bottles that adhere to standards such as ISO and ASTM can vastly affect the approval process of laboratory procedures and outcomes. Such compliance not only highlights the authoritative significance of using the right bottle but also builds trust with clients and stakeholders who rely on accurate and reproducible results. Trustworthiness in the context of extraction reagent bottles stems from their role in guaranteeing the purity and performance of the stored reagents. Laboratories are environments where precision is non-negotiable, and the trust placed in these bottles is immense. An anecdote often shared among seasoned lab professionals is that of the occasional venture when substituting reagent bottles resulted in altered extraction efficiencies. This narrative underscores the critical contribution of a reliable extraction reagent bottle in preserving the integrity of reagents, thereby ensuring consistent and trustworthy outputs. In conclusion, the extraction reagent bottle is an indispensable asset for any laboratory or industrial operation involved with chemical extractions. By selecting the right bottle, professionals can enhance their operational efficiency, uphold high standards of safety and compliance, and foster an environment of trustworthiness. As technology advances, the development of even more sophisticated reagent bottles will undoubtedly continue to support the ever-growing demands for precision and safety in chemical processes, cementing their role as vital components in the scientific community.

Share

Latest news

-

Wholesale Plastic Juice Bottles with Caps 16 oz Options Available Bulk Packaging SolutionsNewsJun.10,2025

-

Laboratory Apparatus Reagent Bottle – Durable & Chemical Resistant Bottles for Safe StorageNewsJun.10,2025

-

Squeezable Dropper Bottles Durable, Leak-Proof & CustomizableNewsMay.30,2025

-

Affordable Plastic Petri Plates Sterile & Disposable Lab-GradeNewsMay.30,2025

-

Eye Dropper Caps Precision 24/410 & Plastic Bottle-Compatible TipsNewsMay.30,2025

-

Affordable Mini Spray Bottle Price & Wholesale Deals Shop NowNewsMay.29,2025

RECOMMEND PRODUCTS