/home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/861/header-lBanner.php on line 27

https://www.wahmg.com/)">

https://www.wahmg.com/)">

injection moulding bottles

1 月 . 19, 2025 01:34

Back to list

injection moulding bottles

Injection moulding bottles has become an essential process in the manufacturing sector, offering a versatile and efficient method for producing high-quality plastic containers used across various industries. This article delves into the intricacies of injection moulding for bottles, illustrating its significance and highlighting the expertise required to excel in this field.

Quality control remains the backbone of injection moulding bottles' success. Comprehensive testing and inspection procedures ensure that each batch of bottles meets regulatory and client standards. Experience in creating stringent quality control protocols and the ability to interpret data accurately engenders trust among clients, reassuring them of the consistent quality of the products they receive. Sustainability is a growing concern in the injection moulding industry. As environmental considerations become an integral component of manufacturing, industry leaders are prioritizing eco-friendly practices. From selecting recyclable materials to minimizing waste during production, an authoritative approach toward sustainability not only meets environmental regulations but also aligns with consumer expectations. Moreover, continuous professional development is essential in this ever-evolving field. Industry experts frequently engage with new research, attend conferences, and participate in training programs to stay abreast of technological advancements and regulatory changes. This commitment to lifelong learning not only enhances expertise but also establishes a reliable reputation within the market. Collaboration and communication with clients throughout the production process enhance trustworthiness. Understanding the unique needs and specifications of each client allows for the customization of solutions. A transparent approach, where challenges are communicated and solutions are devised collaboratively, fosters a strong relationship between manufacturer and client. In summary, injection moulding bottles is a sophisticated process that requires a deep understanding of materials, technology, and quality control. By embracing sustainable practices and continuous learning, professionals in this industry maintain an authoritative and trustworthy presence. This commitment to excellence ensures that they not only meet but exceed the expectations of a diverse clientele while contributing to a more sustainable planet.

Quality control remains the backbone of injection moulding bottles' success. Comprehensive testing and inspection procedures ensure that each batch of bottles meets regulatory and client standards. Experience in creating stringent quality control protocols and the ability to interpret data accurately engenders trust among clients, reassuring them of the consistent quality of the products they receive. Sustainability is a growing concern in the injection moulding industry. As environmental considerations become an integral component of manufacturing, industry leaders are prioritizing eco-friendly practices. From selecting recyclable materials to minimizing waste during production, an authoritative approach toward sustainability not only meets environmental regulations but also aligns with consumer expectations. Moreover, continuous professional development is essential in this ever-evolving field. Industry experts frequently engage with new research, attend conferences, and participate in training programs to stay abreast of technological advancements and regulatory changes. This commitment to lifelong learning not only enhances expertise but also establishes a reliable reputation within the market. Collaboration and communication with clients throughout the production process enhance trustworthiness. Understanding the unique needs and specifications of each client allows for the customization of solutions. A transparent approach, where challenges are communicated and solutions are devised collaboratively, fosters a strong relationship between manufacturer and client. In summary, injection moulding bottles is a sophisticated process that requires a deep understanding of materials, technology, and quality control. By embracing sustainable practices and continuous learning, professionals in this industry maintain an authoritative and trustworthy presence. This commitment to excellence ensures that they not only meet but exceed the expectations of a diverse clientele while contributing to a more sustainable planet.

Share

Prev:

Latest news

-

Wholesale Plastic Juice Bottles with Caps 16 oz Options Available Bulk Packaging SolutionsNewsJun.10,2025

-

Laboratory Apparatus Reagent Bottle – Durable & Chemical Resistant Bottles for Safe StorageNewsJun.10,2025

-

Squeezable Dropper Bottles Durable, Leak-Proof & CustomizableNewsMay.30,2025

-

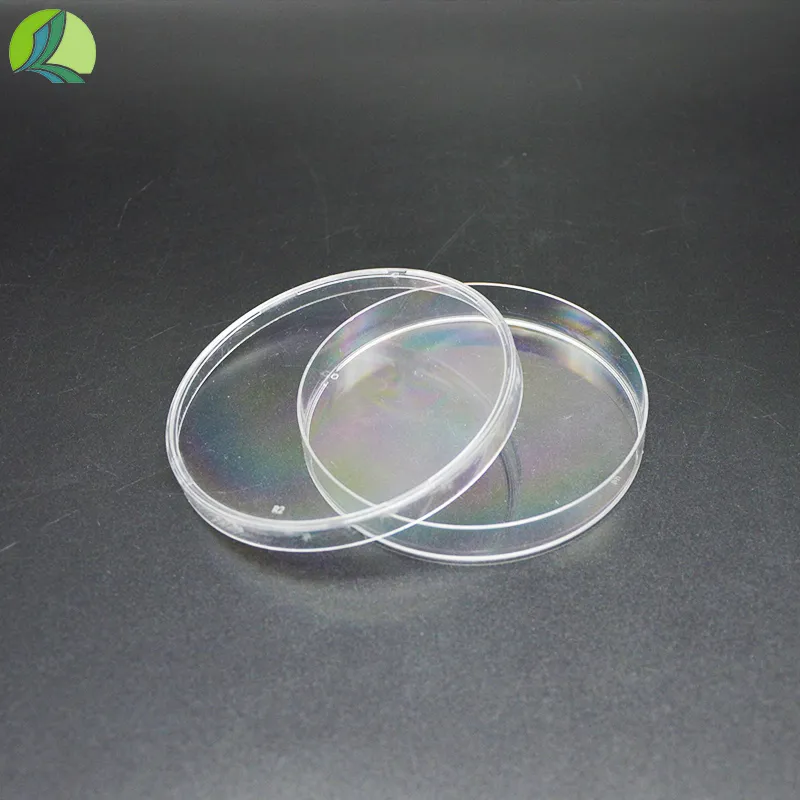

Affordable Plastic Petri Plates Sterile & Disposable Lab-GradeNewsMay.30,2025

-

Eye Dropper Caps Precision 24/410 & Plastic Bottle-Compatible TipsNewsMay.30,2025

-

Affordable Mini Spray Bottle Price & Wholesale Deals Shop NowNewsMay.29,2025

RECOMMEND PRODUCTS