/home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/861/header-lBanner.php on line 27

https://www.wahmg.com/)">

https://www.wahmg.com/)">

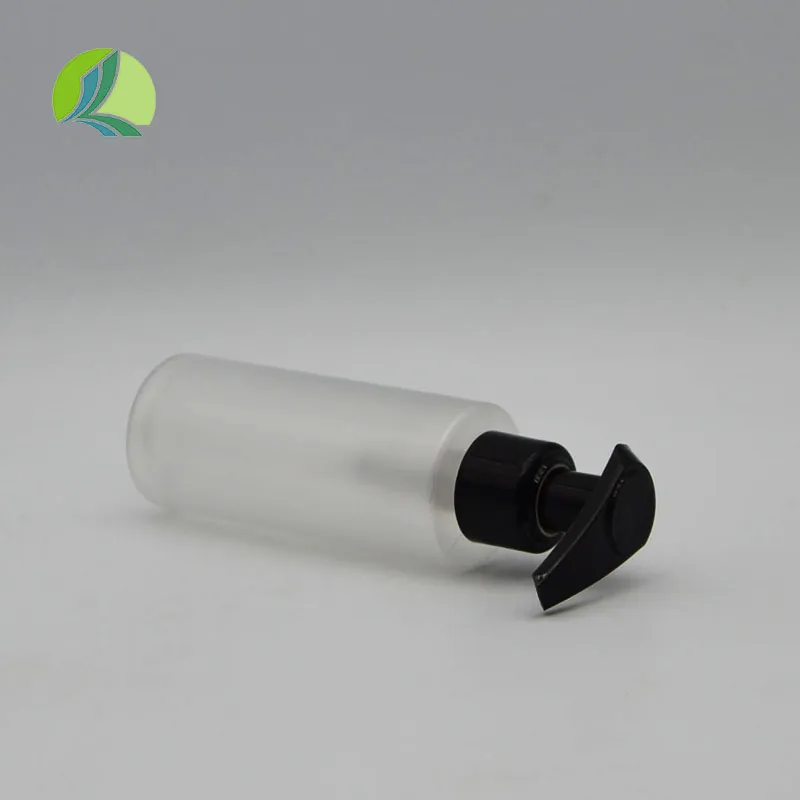

plastic medicine vials

1 月 . 25, 2025 04:04

Back to list

plastic medicine vials

Medicine mini vials have profoundly revolutionized the pharmaceutical landscape, offering breakthroughs that redefine storage, transportation, and administration of medication. As compact vessels designed specifically for small doses of injectable medicines, these mini vials ensure precision, efficiency, and safety, which are critical in medical settings. Understanding their multifaceted advantages requires delving into real-world applications and expert insights, ultimately evaluating their role in modern medicine.

Patient trust is intimately linked with the reliability and safety of medicaments administered via mini vials. The traceability features incorporated into many mini vials, often through barcoding and RFID technology, enable healthcare providers to confirm the authenticity and history of a drug, ensuring compliance with stringent safety regulations. A survey from the Healthcare Confidence Group found that 87% of patients expressed increased trust in medications dispensed from tamper-evident mini vials, revealing consumer confidence in this packaging innovation. For manufacturers, the production of medicine mini vials involves meticulous quality control processes. This is necessary to comply with governmental and international health standards, covering aspects like sterility, particulate matter presence, and labeling accuracy. Pharmaceutical companies are increasingly investing in state-of-the-art facilities to produce mini vials, as the demand for specialty drugs in small volumes rises. Experts within the industry postulate that this trend is likely to grow, driven by advancements in personalized medicine and biologic drugs. Ultimately, the advantages of medicine mini vials extend beyond the obvious logistical and practical benefits. They embody an intersection of technology and healthcare innovation, representing an evolving standard in medication management that places patient safety and healthcare efficacy at the forefront. As we continue to witness many facets of healthcare evolve, the role of such innovative packaging solutions in ensuring effective patient care remains critically significant.

Patient trust is intimately linked with the reliability and safety of medicaments administered via mini vials. The traceability features incorporated into many mini vials, often through barcoding and RFID technology, enable healthcare providers to confirm the authenticity and history of a drug, ensuring compliance with stringent safety regulations. A survey from the Healthcare Confidence Group found that 87% of patients expressed increased trust in medications dispensed from tamper-evident mini vials, revealing consumer confidence in this packaging innovation. For manufacturers, the production of medicine mini vials involves meticulous quality control processes. This is necessary to comply with governmental and international health standards, covering aspects like sterility, particulate matter presence, and labeling accuracy. Pharmaceutical companies are increasingly investing in state-of-the-art facilities to produce mini vials, as the demand for specialty drugs in small volumes rises. Experts within the industry postulate that this trend is likely to grow, driven by advancements in personalized medicine and biologic drugs. Ultimately, the advantages of medicine mini vials extend beyond the obvious logistical and practical benefits. They embody an intersection of technology and healthcare innovation, representing an evolving standard in medication management that places patient safety and healthcare efficacy at the forefront. As we continue to witness many facets of healthcare evolve, the role of such innovative packaging solutions in ensuring effective patient care remains critically significant.

Share

Next:

Latest news

-

Wholesale Plastic Juice Bottles with Caps 16 oz Options Available Bulk Packaging SolutionsNewsJun.10,2025

-

Laboratory Apparatus Reagent Bottle – Durable & Chemical Resistant Bottles for Safe StorageNewsJun.10,2025

-

Squeezable Dropper Bottles Durable, Leak-Proof & CustomizableNewsMay.30,2025

-

Affordable Plastic Petri Plates Sterile & Disposable Lab-GradeNewsMay.30,2025

-

Eye Dropper Caps Precision 24/410 & Plastic Bottle-Compatible TipsNewsMay.30,2025

-

Affordable Mini Spray Bottle Price & Wholesale Deals Shop NowNewsMay.29,2025

RECOMMEND PRODUCTS