/home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/861/header-lBanner.php on line 27

https://www.wahmg.com/)">

https://www.wahmg.com/)">

plastic medicine bottle

1 月 . 26, 2025 06:03

Back to list

plastic medicine bottle

In the intricate world of medical supplies and healthcare, plastic medicine bottles hold a paramount position. Their ubiquitous presence in hospitals, pharmacies, and households underscores their significance in safely storing a wide array of medications. These bottles serve as the frontline guardians against contamination, spillage, and dosage errors, all while maintaining the integrity of the contained pharmaceuticals.

Authoritativeness in the domain of plastic medicine bottles is underscored by stringent regulations and standards set by authoritative bodies like the U.S. Food and Drug Administration (FDA) and the International Organization for Standardization (ISO). These organizations mandate rigorous testing for plastic medicine bottles, ensuring they meet high standards for safety, quality, and performance. Compliance with such regulations is not merely a recommendation but a requirement, positioning manufacturers who adhere to these guidelines as leaders in the field. The empirical data and research produced by these authorities lend credibility and weight to the claims regarding the safety and efficacy of plastic medicine bottles, reinforcing their essential role in healthcare. Trustworthiness is paramount when it comes to products that impact public health, and plastic medicine bottles are no exception. Trust is built through transparency in manufacturing processes, adherence to safety standards, and responsiveness to consumer feedback. Companies that produce these bottles often engage in open dialogue with healthcare professionals and consumers alike, addressing concerns and incorporating suggestions to improve their products. Furthermore, advancements in traceability mechanisms, like QR codes, allow consumers to verify the authenticity and safety of their medicine containers, providing peace of mind and establishing a reliable connection between manufacturers and end-users. In summary, plastic medicine bottles exemplify a confluence of experience, expertise, authoritativeness, and trustworthiness. Their pivotal role in the healthcare system, bolstered by scientific innovation and regulatory compliance, underpins their status as indispensable tools in medication management. As global healthcare needs evolve, so too will the technologies and standards governing these vessels, ensuring they remain at the forefront of safe and effective medicinal storage solutions.

Authoritativeness in the domain of plastic medicine bottles is underscored by stringent regulations and standards set by authoritative bodies like the U.S. Food and Drug Administration (FDA) and the International Organization for Standardization (ISO). These organizations mandate rigorous testing for plastic medicine bottles, ensuring they meet high standards for safety, quality, and performance. Compliance with such regulations is not merely a recommendation but a requirement, positioning manufacturers who adhere to these guidelines as leaders in the field. The empirical data and research produced by these authorities lend credibility and weight to the claims regarding the safety and efficacy of plastic medicine bottles, reinforcing their essential role in healthcare. Trustworthiness is paramount when it comes to products that impact public health, and plastic medicine bottles are no exception. Trust is built through transparency in manufacturing processes, adherence to safety standards, and responsiveness to consumer feedback. Companies that produce these bottles often engage in open dialogue with healthcare professionals and consumers alike, addressing concerns and incorporating suggestions to improve their products. Furthermore, advancements in traceability mechanisms, like QR codes, allow consumers to verify the authenticity and safety of their medicine containers, providing peace of mind and establishing a reliable connection between manufacturers and end-users. In summary, plastic medicine bottles exemplify a confluence of experience, expertise, authoritativeness, and trustworthiness. Their pivotal role in the healthcare system, bolstered by scientific innovation and regulatory compliance, underpins their status as indispensable tools in medication management. As global healthcare needs evolve, so too will the technologies and standards governing these vessels, ensuring they remain at the forefront of safe and effective medicinal storage solutions.

Share

Latest news

-

Wholesale Plastic Juice Bottles with Caps 16 oz Options Available Bulk Packaging SolutionsNewsJun.10,2025

-

Laboratory Apparatus Reagent Bottle – Durable & Chemical Resistant Bottles for Safe StorageNewsJun.10,2025

-

Squeezable Dropper Bottles Durable, Leak-Proof & CustomizableNewsMay.30,2025

-

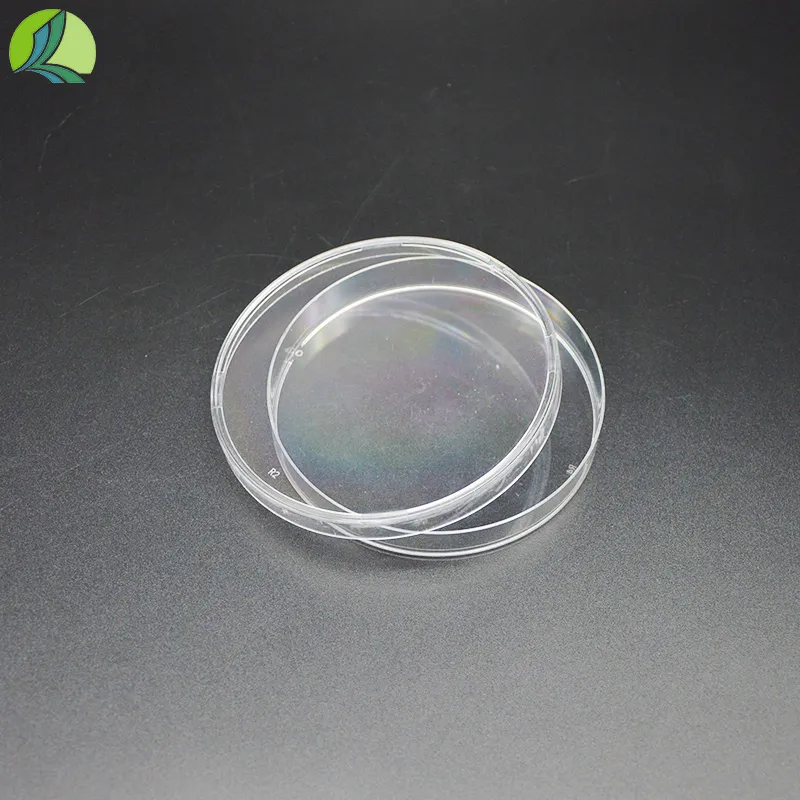

Affordable Plastic Petri Plates Sterile & Disposable Lab-GradeNewsMay.30,2025

-

Eye Dropper Caps Precision 24/410 & Plastic Bottle-Compatible TipsNewsMay.30,2025

-

Affordable Mini Spray Bottle Price & Wholesale Deals Shop NowNewsMay.29,2025

RECOMMEND PRODUCTS